Prototyping is a critical aspect of product design services. It allows industrial designers to test and improve upon their ideas before starting production. Not all prototypes are created the same, and different versions of prototypes have various purposes. This article will discuss the different versions of prototypes involved in product development and explain the need for multiple types of prototype methods.

Different Types of Prototypes

The Proof of Concept Prototype

Before product design companies embark on three-dimensional computer-aided software (3D CAD), they have to make a proof of concept prototype, which they will accomplish by either carving it out of foam, cutting and gluing foam board, or using clay. This prototype is critical because it proves that the general concept functions properly and practices good ergonomics.

The 3D Printed Prototype

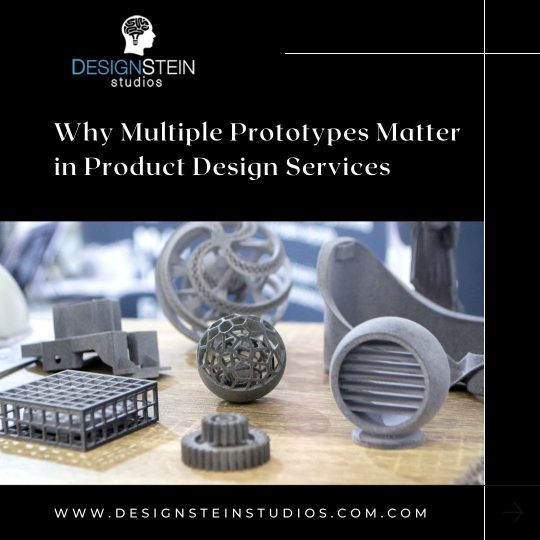

Once an industrial design company starts 3D CAD, the design team will start work on 3D printing the prototypes. The intent of this prototype is to test all of the following criteria: fitment, size, mechanisms, and functionality. This prototype is more precise than the previous one but not entirely as accurate as the following type of prototype. The 3D printing prototype process repeats until the prototype appears and functions properly.

The CNC Prototype

Before a design team opens tooling, they will create a 3rd type of prototype, the Computerized Numerical Control, more commonly referred to as the CNC version. This process involves a huge chunk of plastic being cut away with rotating machinery. The intent of this prototype is to test the product’s functionality. Once the designers feel confident about how it functions, they will open tooling and proceed to the final prototype.

The Visual Model Prototype

The final type of prototype is the visual model. This prototype will appear and function just like the production unit. In making the visual model, a silicone mold is made from the CNC prototype, removed from the mold, and liquid resin is poured into the silicone mold. Once it dries, the silicone mold is taken, leaving a piece with the right colors, textures, and logos as a manufactured unit. This prototype is used for the following marketing purposes:

- Display at trade shows

- To make videos or photos for websites

- To share on social media platforms.

Why You Need Multiple Prototypes

Each prototype version has a different, yet equally important, purpose in the product design pipeline. The proof of concept prototype helps designers figure out if their original ideas are achievable and meet ergonomic standards. The 3D-printed prototype allows designers to test the product’s mechanics and functionality. The CNC prototype represents the product’s appearance in production, making designers confident to start tooling. Lastly, the visual model prototype allows designers to display the finished product to important people, such as potential customers and prospective investors.

Conclusion

Prototyping is essential to product design services. Multiple types of prototypes, each with a different purpose, are crucial to ensure the finished product meets specific standards. From proof of concept to the visual model, each type of prototype improves upon the last, resulting in a finished product that is functional, visually appealing, and profitable.