You’re surrounded by industrial design nearly every minute of the day, whether you realize it or not. The chair you’re sitting on, the cup you drink your coffee from, and everything down to the bicycle or bus seat where you spend your commute are all products of what is known as industrial design.

But what does industrial product design entail? We often overlook the planning and development that goes into industrial designers transforming the everyday items we use into aesthetically pleasing products. Keep reading for a look at what’s at the core of industrial design, its history, the design process, and some thoughts on the future of industrial design and why it plays such a pivotal role in our daily lives.

What Is Industrial and Product Design?

Industrial product design is the strategic process of creating aesthetic, user-friendly, functional, and readily marketable products. Industrial design is an art that integrates form and function — and the subtlety of problem-solving in the process — of crafting products that people need and appreciate.

The importance of industrial product design becomes apparent when considering the effective synergy of the different disciplines it represents. It combines creativity, technical knowledge, and business strategy to determine an industrial design process that delivers the highest quality, lowest cost product possible.

But why is it important? Naturally, users want a product to be user-friendly and visually appealing. Imagine a mobile phone that’s too large, small, complicated, or otherwise difficult to use. Consumers wouldn’t like it, and it wouldn’t sell well. That’s precisely where industrial product design comes in. It ensures the products you bring to market have an intuitive, attractive form and an aesthetic appeal.

Industrial design involves a lot more than creating a working user interface. Even before industrial designers create prototypes, manufacturing methods and production costs will inform the design process to ensure a product that looks good and functions well — and can provide a competitive advantage over similar products.

By leveraging the manufacturing processes to minimize production costs, skilled industrial designers can develop and oversee industrial design methods that ensure the creation of economically produced products with broad consumer appeal that can contribute to your overall business success.

Let’s take the example of a household staple in many parts of the world — the electric kettle. Its use dictates an ergonomic design with a non-drip spout and an insulated handle that stays comfortable to hold. These are all elements of a careful and thoughtful industrial design process. Each aspect caters to its functionality — heating water — and its ease of use and safety.

It becomes clear just how much industrial and product design impact our everyday lives. If you’re a decision-maker or stakeholder of a company tasked with bringing products to a discerning and demanding marketplace, working with the right industrial designers allows you to co-create solutions that can make the difference between success and failure. By carefully examining various aspects of different manufacturing processes, talented industrial designers can ensure a product is made with functional, durable, attractive, and cost-effective materials.

History and Evolution of Industrial Design

With its roots in the artisanal crafts of the previous century, industrial design began in the 19th century as a response to the thriving Industrial Revolution. The era of mass production meant machine-made counterparts replaced handmade goods.

Although the earliest industrial product design was little more than creating a design process culminating in readily reproducible manufactured goods, it soon became a more refined and developed field. Before the dawn of the 20th century, engineers and craftsmen typically carried out product design. But as the Industrial Revolution ushered in an era of mass-produced goods, it became increasingly crucial to have designers who could balance functionality and aesthetic appeal in product creation.

The distinct profession of industrial design began to take shape in the early 20th century, with Joseph Claude Sinel being one of its earliest proponents. In 1919, Sinel’s view of industrial design would influence everything that came after. In short, his philosophy could be called the blending of art and industry to achieve the highest quality in material products for the consumer’s benefit.

The aftermath of the war years witnessed a surge in the growth of industrial design. This was primarily attributed to burgeoning consumerism and escalating demand for stylish yet reasonably-priced products. Legendary designers like Raymond Loewy, Walter Dorwin Teague, and Dieter Rams significantly influenced the design and utility of the products we’re familiar with today.

Loewy was acclaimed for his streamlined industrial design, visible in his creations like the Coca-Cola Contour bottle and Studebaker Avanti car. Teague was the trailblazer in corporate identity design, and he crafted the logos and corporate identities for numerous big players, including General Electric and AT&T. Meanwhile, Rams, a German designer, won accolades for his minimalist and functional designs for Braun appliances.

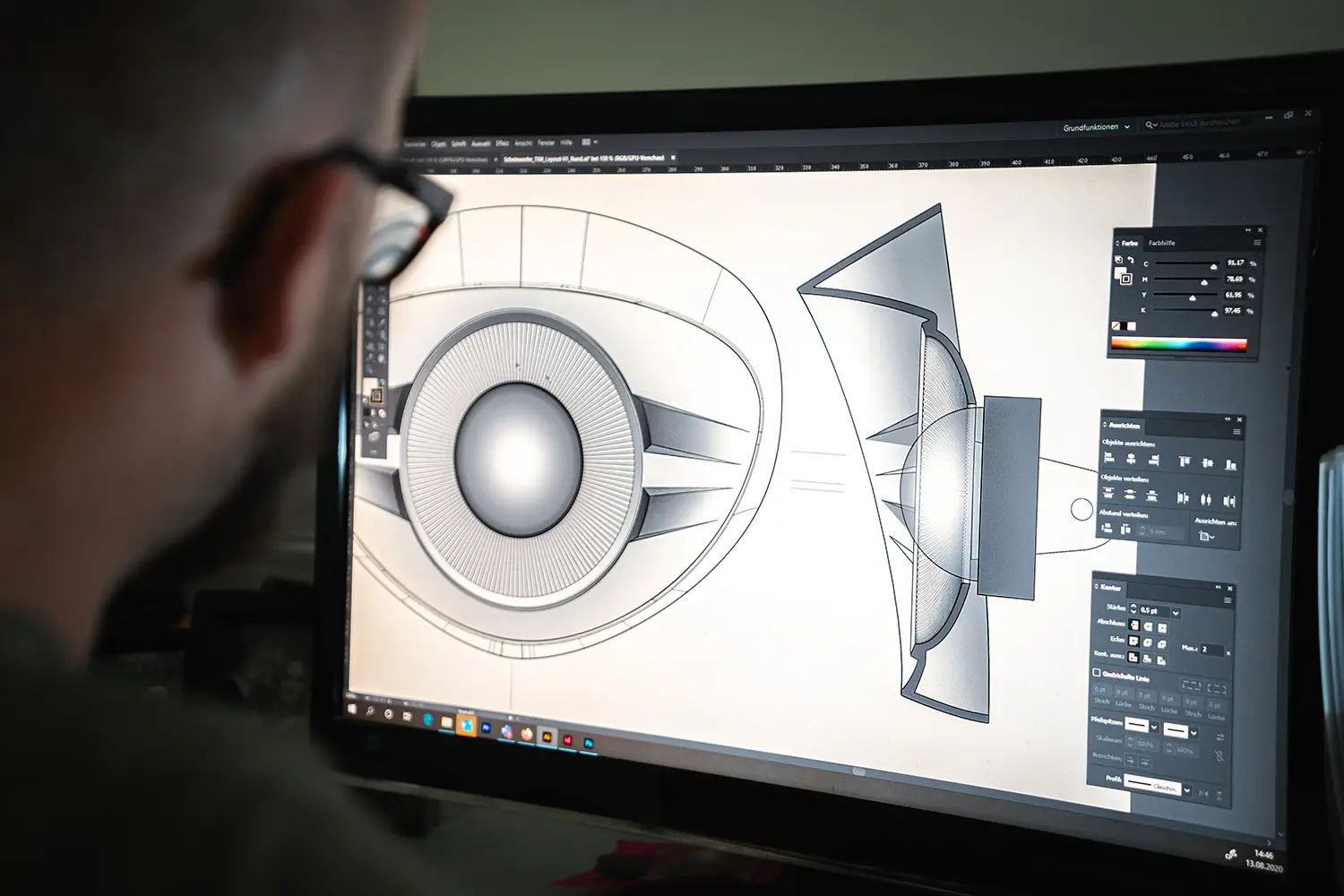

These pioneers focused on creating aesthetic, user-friendly, and marketable products in response to growing consumer demand. But industrial design wasn’t static; it evolved with technology and societal changes. The arrival of computers brought about Computer-Aided Design (CAD), streamlining the design process. Today’s industrial design is an amalgamation of conventional practices enhanced by digital tools and critical sensitivity to sustainable practices.

The Design Process

Every manufactured item you see is the product of deliberate industrial product design. Industrial design is a meticulous journey from the birth of an idea to the final product, carefully shepherded at each step by skilled and talented industrial designers.

At DesignStein, the industrial product design process begins with recognizing and understanding a problem area. It could start with a simple question like, “How can we make morning coffee more enjoyable?” or “How can we make this mobile phone easier to use?” Industrial designers then dive into research by studying existing solutions, understanding user behavior and needs, and identifying technological possibilities.

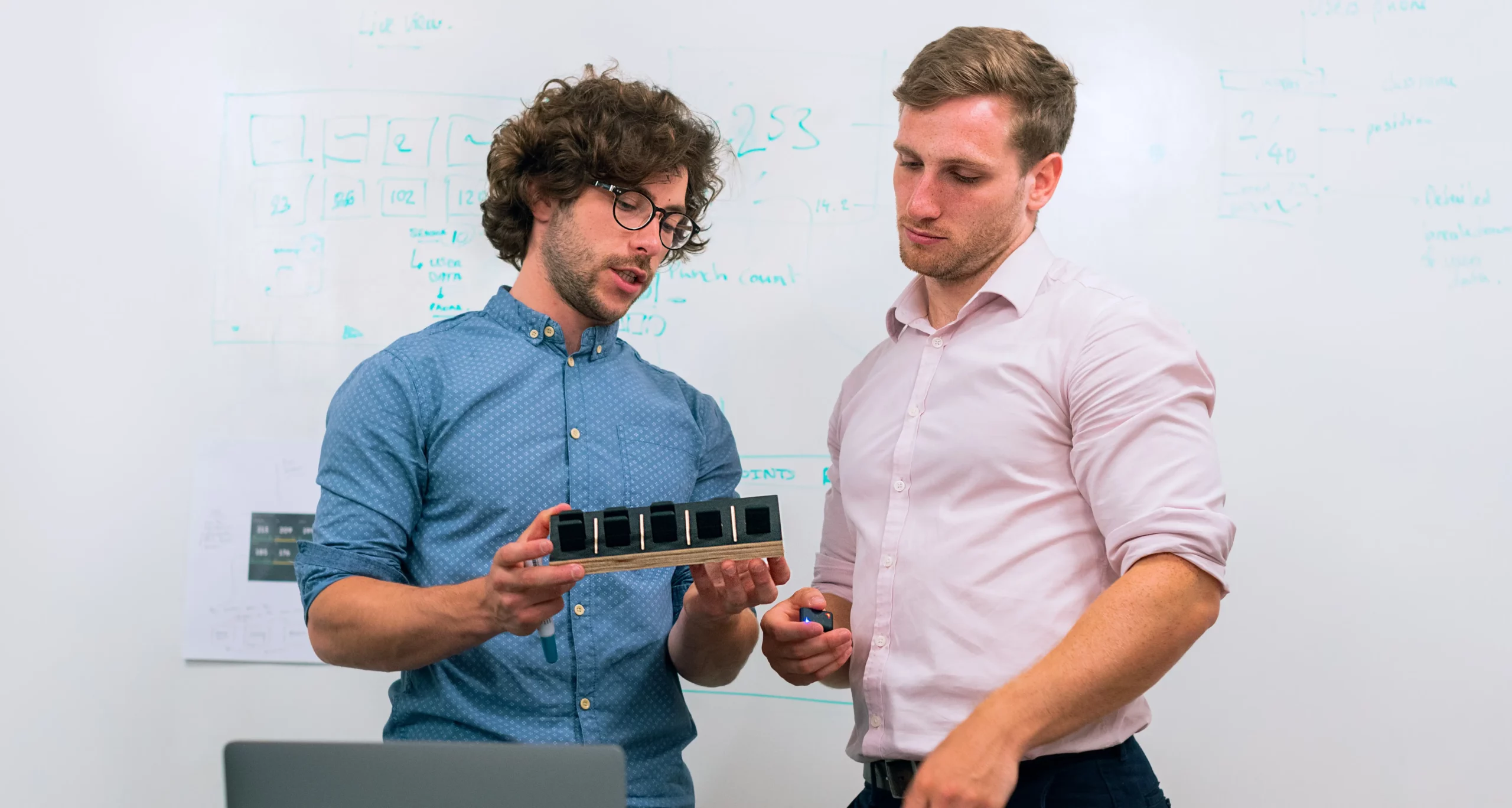

This involves market, manufacturing, and user research, helping to paint a clear picture of what must be solved, how, and for whom. Industrial designers brainstorm, sketch ideas, and create prototypes. The best concepts are chosen and refined. This iterative process leads to the development phase, where the final product design is formed.

The last step of the design process is execution, where the final product is manufactured. But the industrial designer’s job doesn’t end here. They oversee production and manufacturing processes, ensuring the final product aligns with the original design and intent.

This may not always be straightforward; changes may and do occur. However, each step brings the designer closer to creating a product that can effectively, economically, and attractively solve a consumer’s problem and ease whatever pain point the product was designed to address.

Roles and Responsibilities of an Industrial Designer

An industrial designer transforms a concept or need into a tangible, feasible, and market-ready product. Industrial design is responsible for the overall visual appearance of the product, ensuring that it’s not just sophisticated and visually appealing but also functional, with easy-to-use controls and an intuitive user interface for the end consumer.

Industrial designers are tasked with much more than spending hours in the drawing board phases of industrial product design. Industrial designers must also be savvy in understanding market trends, consumer needs, and technical constraints. Industrial design intersects and collaborates with marketing teams, engineers, and business strategists to ensure the end product aligns with consumer expectations and business goals.

The Future of Industrial Design

The needs of an ever-more demanding marketplace and consumers with increasingly sophisticated needs make it clear that industrial design is set for a dynamic journey ahead. The integration of technology, particularly the rise of artificial intelligence (AI) and 3D printing, is reshaping the design process and allowing for increased precision and personalization. Advancements in sustainable materials and techniques are pushing industrial designers to reevaluate design practices and embrace eco-friendly methods.

As society becomes more digitally oriented, the overlap between industrial design and user interface design is becoming more nuanced and complex. In the global drive towards creating smart, connected products, industrial designers will continue to play a pivotal role, evolving in response to our changing world.

Your Choice of Industrial Design Partner

Many industrial design firms claim to be an all-encompassing, one-stop-shop solution, managing everything from research and idea generation to manufacturing, quality control, and shipping. However, most often, these claims are only partially true. These firms are either design-centric with industrial designers who have little to no experience regarding manufacturing and production, or they lack creativity and insight into manufacturing constraints.

DesignStein bridges this divide with our team of industrial designers, bringing designs to life at every stage of the development and manufacturing process. This doesn’t mean every client has to use all of our industrial design services — we’re flexible and can seamlessly adapt to the client’s needs at any stage of the product development process.

Many industrial design companies can create visually stunning products, but can their industrial designers develop products that align with your pricing strategy to ensure profitability? We prioritize cost-effectiveness from the earliest stages of design.

DesignStein’s industrial designers aim to make our designs aesthetically pleasing and functionally superior while ensuring they can be produced at a cost that aligns with your budget — and your bottom line.