The next time you go out shopping at your favorite hypermarket and see the vast array of products meticulously lined up on the shelves, stop and think about what an industrial design company has to go through to manufacture these products. The majority of these products are mass-manufactured using expensive processes such as injection molding. Although it allows design companies like Designstein Studios to produce a massive assortment of products, it also needs forming and manufacturing very costly tools.

How Does Advanced 3D Printing Make Intricate Parts More Attainable?

The more complicated the part, the more money and time you usually have to invest in it. Fair enough! If you have to produce millions of these parts, it might be economically feasible, but if you are just producing thousands it definitely won’t work out to be cost-effective.

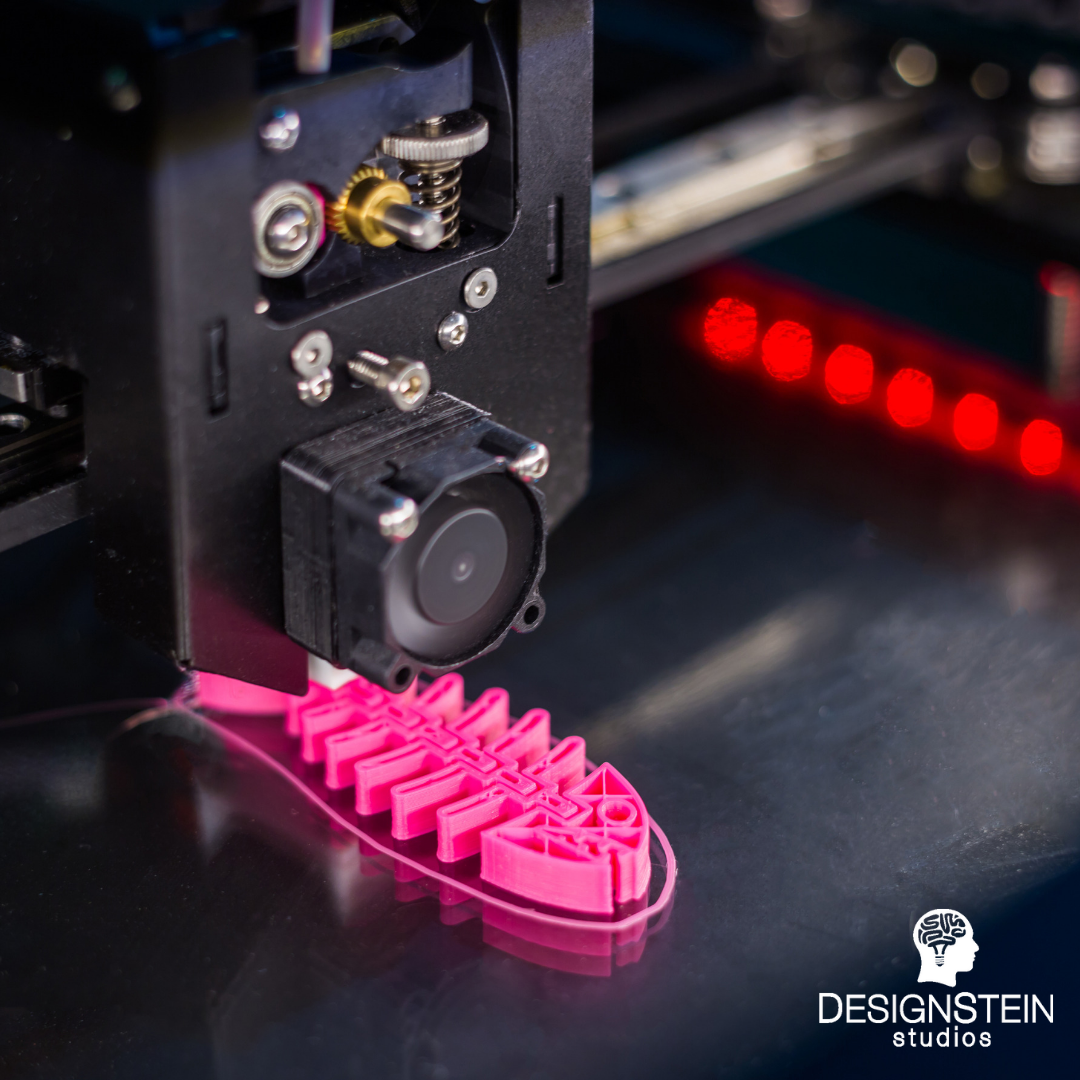

For this reason, Designstein Studios are using a more cutting-edge approach to manufacturing their innovators’ products and that is 3D printing. 3D printing, or sometimes referred to as additive manufacturing, makes brief production of complex parts a more doable alternative.

By just creating a pattern that is suitable for a 3D printer, an industrial design company can produce a large number of parts way quicker and at a very low cost, in a wide range of materials and designs.

Old-school manufacturing has many restrictions and you can only go as far as creating simpler parts that usually take over a month to get your hands on. Advanced 3D printing methods make it as easy as pie to design complicated parts and acquire up to thousands of them in less than a week.

Not only is 3D printing great at creating parts quicker, but you can also simplify complicated parts. Perhaps your product has a sophisticated part that when using traditional manufacturing techniques requires it to be created in numerous pieces and needs fasteners, seals, inserts and extra assembly steps; but can be formed as an individual part that is practical as soon as it gets off the production line. 3D printing can simplify the production of otherwise elaborate and complex parts.

How Is 3D Printing Pushing The Designing Limits?

Despite the fact, the above points are very exciting indeed, the most impressive aspect of 3D printing for quick as a wink manufacturing is how it is pushing the limits of design. Unique and extraordinary features that would be unattainable using long-established manufacturing methods are made achievable with 3D printing. For instance, one company was able to develop the first residential faucets with intricate latticework design with the help of 3D printing.

If traditional methods were used, making these domestic faucets properly structured, weightless, and hollow it would be practically impossible; and if there was any chance of making them, they would be extremely expensive to make. 3D printing allows an industrial design company to create these features easily while drastically lowering tooling costs.

Designstein Studios has helped many innovators see their products materialize with the means of 3D printing. This helps designers, many of who are working with a small budget, create their awesome products with very little costs and can only sell a few and still turn a profit. Those days of having a big production run in the millions are over and done. Nowadays, manufacturing is simpler, easy on the pocket-book, and gives the green light for innovators to be more experimental with their designs.